VICTORIA‘S WINDOW

VICTORIA’S WINDOW

Details of soldered lead with front lighting (left) and backlighting (right)

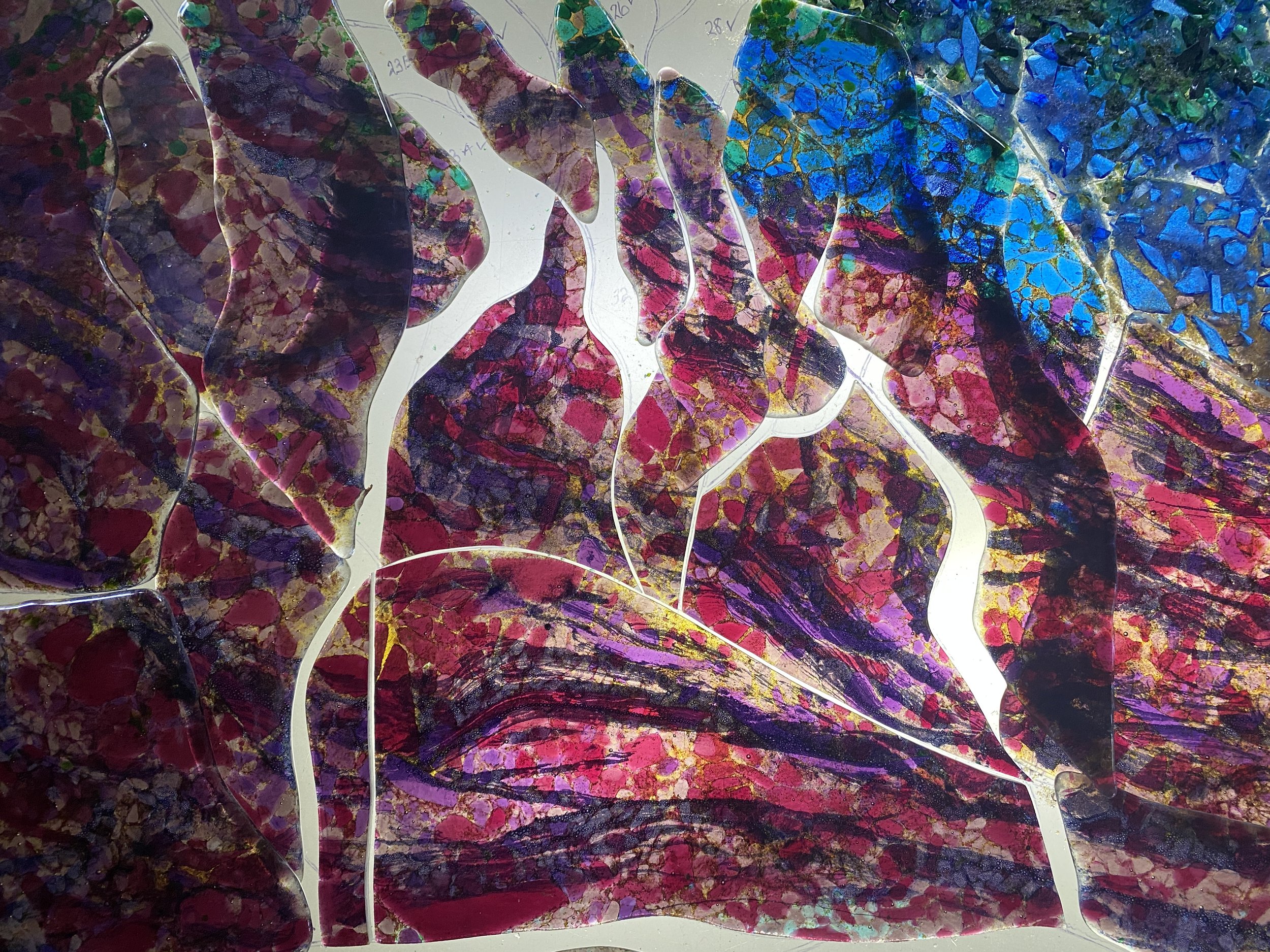

Over the base glass, I added multiple layers of stained glass frit (crushed glass in various sizes) as well as larger carefully cut pieces. This looks like a collage/sandpainting before all the sections are moved to the kiln for firing.

Victoria’s Window, 2023, Fused stained glass with metal oxide underpainting, leaded with copper overlays, in carved and welded stainless steel frame. 45” x 58”

Technically, this window is first of a kind and possible one of a kind. A client had shown interest in my Windswept Oaks at Cedar Tree Neck window in my home. It was a leaded stained glass window using hand rolled stained glass. I did two of these windows in 1975 and 1978. They wanted to buy it, but I had lived with it all these years, so I offered to do a version in fused stained glass with special high heart leading. This turned out to be a tremendous amount of work. When cutting regular stained glass, 1/8” thick average, you cut sheet glass to a pattern, then lead the glass pieces. Accurate cutting is crucial for a window to be tight into the lead and have good structure. When fusing stained glass, you cast the shapes bigger than the pattern, then grind the edges to fit perfectly into the lead comes. The problem is that fused glass becomes an average of 1/4”, twice the thickness of stained glass commercial sheets. This grinding and trimming is a tremendous amount of work. This window came out perfectly leaded with great integrity. I just don’t know if I would do it again.

Copper overlays are added to the lead to build out the shapes of the tree trunks.

On The Beach at Cedar Tree Neck, 1978, leaded stained glass, 38” x 49”

After firing the stained glass on top of the base glass, each casting is carefully ground to fit to the paper pattern.

Paper pattern from 1974, I added several inches to all four sides to expand the design to fit the commissioned window opening

After leading with high heart lead comes, I soldered the entire surface, including the copper overlays applied to the surface of the lead. (see above). This video was taken while still on workbench. You can see how strong the colors are even from the front surface.

After cutting all the shapes oversized in base glass, I painted with metal oxides for the wispy effects and the black lines.

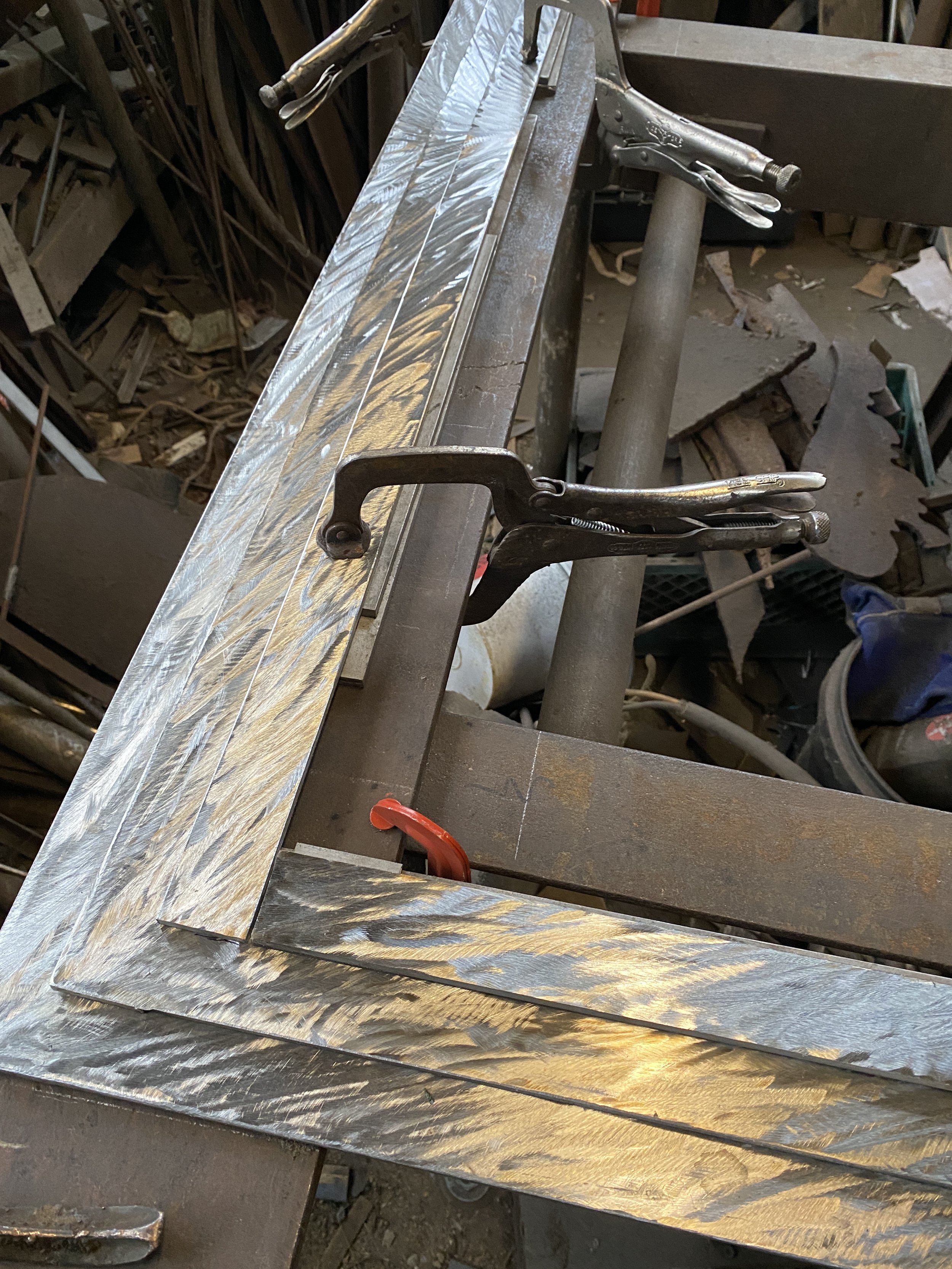

Carved and welded stainless steel frame for Victoria’s Window was three tiered 1.5” bars stacked to make a 4” border all the way around. Other than the frames for the Rodef Shalom Temple and German church former synagogue windows, this is my most exotic frame. Bottom left shows the fastening device on the back of frame. This is a very heavy window. All the glass is 1/4” thick as well as the 1/4” stainless steel bars.